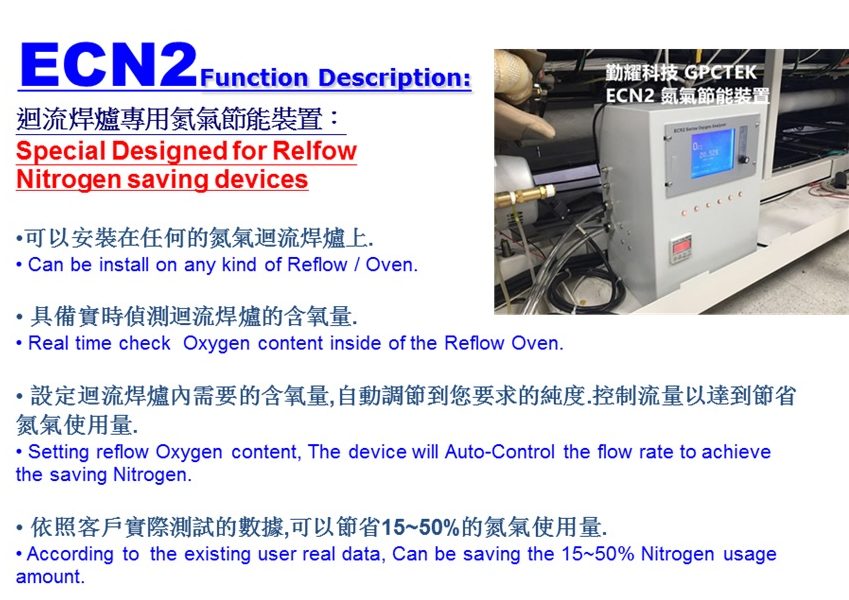

ECN2 is a closed loop Nitrogen saving device uses in Electronics reflow oven. It comprises of a Micro-processor, an Oxygen analyser, and a Pneumatic system to control the flow of Nitrogen.

The advantages of ECN2

- An Oxygen analyser to monitor the O2 ppm level of Reflow Oven.

- A Nitrogen Saving Device: it maintains O2 ppm level in the reflow oven (Production process requirements) and at the same time, saved Nitrogen usage up to 50%.

- Real time monitoring of O2 ppm level in the reflow Oven and Nitrogen flow rate. Keep up to 6 months records for trace purposes.

For more detailed information, please refer to this document.

Nitrogen Saving Device

GPCTek is the manufacturer of superior and proven quality Nitrogen Saving Devices called ECN2. This top-quality device is a closed-loop system and is used in the electronic reflow oven. Pre-tested and inspected, the devices are quality checked to offer an optimized solution to our customers. We take utmost care in quality control, standardization, and quality assurance of our product.

Our Nitrogen Saving Device consists of:

- A microprocessor with an oxygen analyzer and a pneumatic system. All three components work in a synchronized manner in controlling nitrogen flow.

- The oxygen analyzer is a system that assesses the oxygen level in the reflow oven.

- Our cost-efficient system helps save nitrogen use to up to half compared to other standard equipment you are using.

- The system also helps in real-time monitoring and maintaining the oxygen levels in the reflow oven.

- With world-class engineering and design, the Nitrogen saving device from GPCTek helps in monitoring nitrogen flow rate in real-time with the facility to maintain a record of the same for up to six months. The smart system is a big help in reporting and tracking performance.

Why GPCTek Nitrogen saving device?

- Easy to set up, the device is compliant with all kinds of the reflow oven.

- With a smart and intuitive design and engineering, you can keep a check on the oxygen level in real-time.

- No manual intervention is required to save nitrogen. The entire mechanism is automatic.

Records from our customers show that the device has enabled our clients to save between 15% to 50% nitrogen during onsite N2 production.